All You Need To Know About Transmission Gully

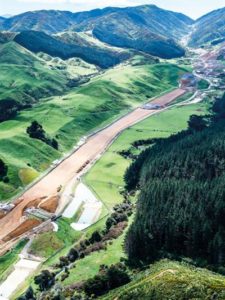

Good progress is being reported on the 27 km, four-lane motorway being constructed from Mackays Crossing to Linden through Transmission Gully, with large-scale earthworks currently the major focus of the project.

Described as a highly complex series of works, the public private partnership (PPP) between the New Zealand Transport Agency (NZTA) and the Wellington Gateway Partnership (WGP) requires navigating difficult and steep terrain, along which 25 new structures equating to over a kilometre in collective length will be constructed. The largest of these, the Cannons Creek Bridge, will stretch 230 m in length and sit 60 m above the valley floor.

- • Moxys – 30 and 40 tonne Cat, Komatsu, Bell and Volvo models

- • Scrapers – Cat 623s, 627s and 637s

- • Diggers – 20 to 65 tonne Hitachi, Cat, Komatsu and Hyundai machines

- • Dozers – Cat and Komatsu 6s, 8s and 10s

- • Compactors – Cat, Bomag, Hamm and Dynapac models.

MAMMOTH BRIDGE STRUCTURES

EARTHWORKS

ON SCHEDULE AND WITHIN BUDGET

NZTA project delivery senior manager Chris Hunt says it is anticipated the Transmission Gully motorway would be included in any network operating contract that is in place at that time, or whatever system management contracting model may be operating.

TRANSMISSION GULLY – THE BENEFITS

- • A safer and more reliable four-lane motorway with a central median barrier and additional crawler lanes on steeper sections

- • Better resilience to landslides, floods and damage to the motorway from a major storm or earthquake

- • Quicker reinstatement than the existing SH1 in the event of a major earthquake

- • Peak-period travel time savings estimated at abound 10 minutes per vehicle between Kapiti and Wellington, 15 minutes between Kapiti and the Hutt Valley, and five to seven minutes between Porirua and the Hutt Valley

- • Easier access from SH1 to Porirua and the Hutt Valley with shorter and more efficient freight movements to and from Seaview/Gracefield, Wingate and the Wairarapa

- • Important arterial connections for residential and light commercial areas in eastern Porirua to the state highway network through two new link roads.

DECISION AWAITED ON TOLLING

- A decision on whether or not to establish a tolling scheme for the Transmission Gully motorway is to be made by the new Minister of Transport Phil Twyford following discussions with Cabinet.

However, prior to a recommendation being made to the minister, the NZTA will conduct traffic and financial modelling, develop a business case and carry out public consultation.

Leave a Reply

Want to join the discussion?Feel free to contribute!